Service information

Hokami provides services in the field of custom electronics production since 1991. We install printed circuit boards with SMT and THT technologies. Most of our projects are processed on the basis of documentation supplied by the customer. We offer the possibility of cooperation in the development of end products.

Production takes place in controlled conditions according to the ISO9001: 2008 standard. The control of products and production operations is governed by the IPC-A-610E standard and individual customer requirements.

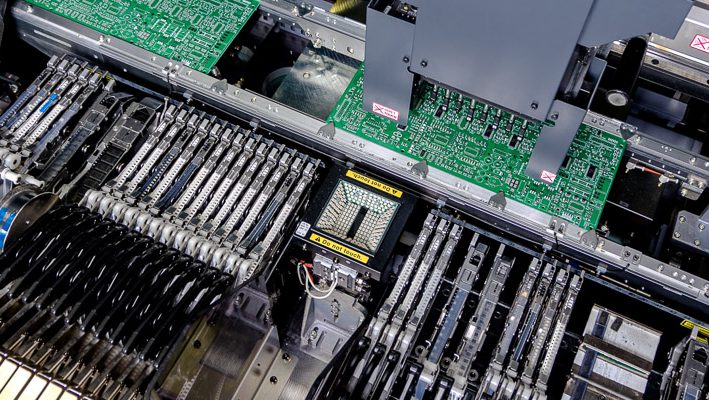

SMD components are mounted on the most modern Yamaha Z machines: Lex and YS24X. We currently operate 4 complete SMT lines. We provide a controlled and supervised process of lead-free and lead soldering throughout the entire production process. We offer mounting of large PCBs up to 810x480mm.

Thanks to regular investments in technology and the development of the company, we always have the most modern equipment. We are thus able to meet almost any customer request. If our technological background does not suit your assignment, we are ready to accept the new challenge and update the equipment so that we can fulfill your wishes as well.

The current capacity of SMT lines is approx. 100 million components per month and the capacity for mounting THT components is approx. 6 million pieces per month.

Equipment with mounting machines:

- 2x Yamaha YSM 20 Z: Lex

- 1x Yamaha YS24X

- 1x Yamaha YSM 20-2B

- 1x Assembly MG1-R

- 1x Assembleon Topaz Xi

Express production:

- Installation - from 24 hours

- Production within 5 days (including provision of PCB and material)

Bonding:

- Golden wire

- Aluminum wire

- Globtop